Spectroscopic Ellipsometer

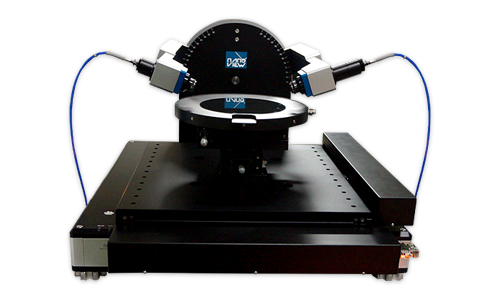

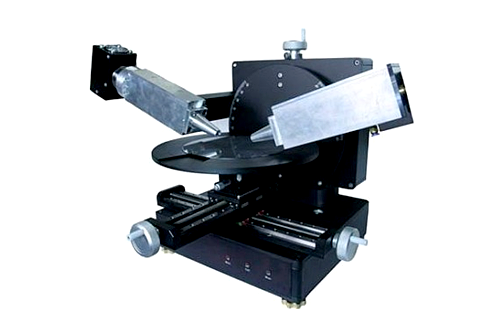

SE MG-1000

- Spectroscopic data measurement

– Visible range: 350~840 nm (or 1.5~3.5 eV)

– Data acquisition speed: 5 sec for full spectra of {Δ, Ψ} - Manually variable angle of incidence

– 45°~90° with 5° step - Single body system

– 40 cm (W) × 30 cm (D) × 30 cm (H), 15 kg (typical)

* UV- option requires external lamp power supply - Easy operation

– No set-up / No keys to control

– Low maintenance - User-friendly software

– operation and analysis - Other features

– Sample stage with tilt & height adjustments

sample size: (5 mm × 5 mm) ~ (200 mm × 200 mm)

– Computer with current operating software - Options

– Mapping stage: manual or automatic

– UV-option: 250~840 nm (or 1.5~5.0 eV)

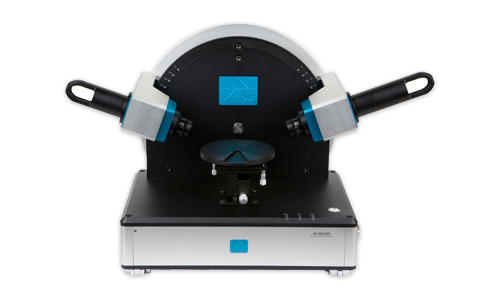

SE MF-1000

- Spectroscopic data measurement

– Visible range: 350~840 nm (or 1.5~3.5 eV)

– Data acquisition speed: 5 sec for full spectra of {Δ, Ψ} - Compact size for mobility

– 28 cm (W)× 20 cm (D)× 6 cm (H), 6kg - Easiest operation in the world

– No set-up / No keys to control

– No effort for alignment (sample faces down)

– Maintenance-free (except lamp )

– Calibration free (patented)* - User-friendly software

– operation and analysis - Other features

– Fixed angle of incidence: 70° ± 0.5°

– Sample size: (8 mm × 8 mm) ~ (200 mm × 200 mm)

– Computer with current operating software

Most ellipsometers require calibration process in each measurement to find the

azimuths of optical elements.

This is a lengthy and complicated process.

SE MF-1000 is calibration free. This makes fast and easy measurement.

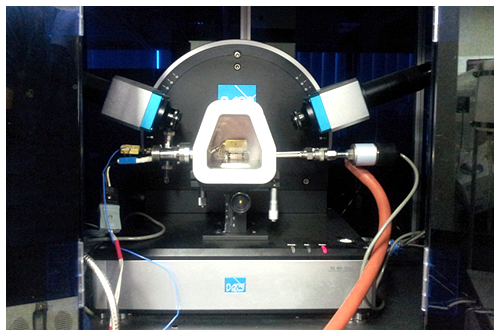

SE MH-1000

- Spectroscopic Ellipsometer Head Type

– Single head type for mapping large-area sample

– Dimension: 25 cm (W)× 15 cm (D)× 30 cm (H)

– Fixed Incident angle

– Wavelength range: 350 ~850 nm

– Data acquisition speed: 5 sec for full spectra of {Δ, Ψ} - Gantry type Stage for Spectroscopic Ellipsometer Head

– Structure: gantry type (Linear motors): X-Y-Z

– Operation: step & repeat

– Max. speed: 0.5 m/s

– Position accuracy: ±10 mm / full scale

– Repeatability: ±5 mm / full scale

– Flatness: 30± mm / full scale

– Straightness: 15± mm / full scale

– Pay load: 20 kg at X-slide - Easiest operation in the world

– Vibration Isolation Table

– Confocal laser scanning microscope

– Contact angle measurement

– 4-point probe

– etc.

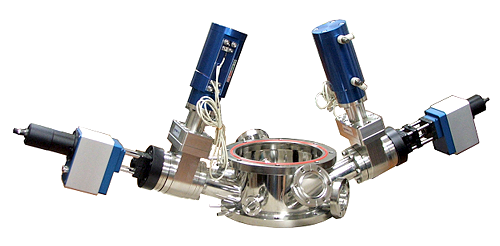

SE MI-1000

- Spectroscopic Ellipsometer Head Type

– Visible range: 350~840 nm (or 1.5~3.5 eV)

* UV-option: 250~840 nm (or 1.5~5.0 eV)

– Data acquisition speed: <5 sec for full spectra of {Δ, Ψ} - Fixed Incident angle - Assistance for In Situ System Design

– Vacuum system

– Heating cell, chemical cell

– Mechanical system for interfacing IN Situ System and ellipsometer - Option

– Optical windows for chamber or cell

– Mechanical shutters for preventing coating on optical windows

– Computer with current operating software

Customized Ellipsometer

Imaging Ellipsometer

- ~0.1 nm thickness difference can be seen by IE-1000.

- Thickness distribution of thin film can be imaged.

- Thickness and optical images of semiconductor device, display, and bio samples.

- IE-1000 can show the images which can not be seen by conventional microscope.

- Defect of semiconductor and display can be seen directly.

- Easy and fast operation.

Vacuum Ellipsometer

- Spectral range down to VUV ( 145 ~ 320㎚)

- Short nitrogen purge time < 5 mins.

- Table top, small foot print.

- Manually variable angle of incidence: 45°~90°

* Application to 193 nm Immersion Lithography

* Easy & accurate measurement of thickness and refractive index for very thin

films of semiconductor

* ARC, PR, high k , oxide, nitride, pellicle and metal.

Near IR Ellipsometer

Micro-spot Ellipsometer

Etc (Rubbins-1000)

- Rubbing Inspection

– 1-D (& 2-D) rubbing strength distribution can be mapped for whole LCD panel.

– Deviation by measurement positions is less than 10% → Quick sample is possible.

– Signal difference among different rubbing condition is distinctive.

– Underlying important part and/or defect can also be distinctively measured.

– In-line or off-line measurement

– Thickness, refractive index {n, k} and uniformity measurement of any thin film

layer including polyimide layer. (optional) - Mapping Stage (whole glass for any generation)

– Travel: 2280 mm × 1920 mm for 7-G

– Max.speed: 0.5 m/s

– Clean room quality

– Vacuum chuck and booth

* Rubbing Inspection for LCD

* Rubbing Strength Measurement for Process Control

* Optical Axis Measurement in LC Alignment Layer

* Whole Glass without Rotation, Off- & In-Line System

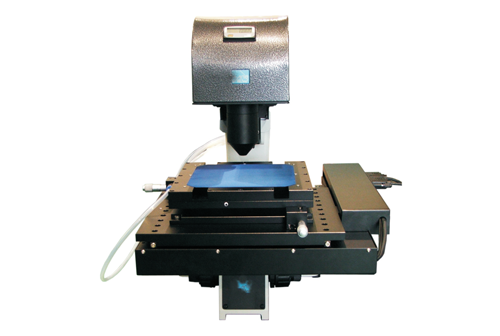

Spectroscopic Reflectometer

SR MR-1000

SR MR-2000

- Application

– Antireflective coating (ARC) on textured (poly-) crystalline silicon solar cell - Measurement

– Thickness, Reflectivity, n&k - Wavelength

– 420 – 950 nm (1.3-3.0 eV) : expandable - Accuracy (thickness measurement on specular sample)

– 104.5 nm for 104.8 nm SiO₂on c-Si

* Accuracy can be dependent on the quality of film - Thickness range

– 10 nm ~ 20 mm (depend on sample) - Data acquisition time

– < 1 s - Beam spot size

– ~ 50 mm - Focusing of beam

– Manual (optional auto-focus) - Sample stage

– Manual X-Y stage (specify sample size and travel distance)

(optional automatic X-Y stage for mapping)